Dear my colleagues,

Today, I will start the series of sequence and phase PLC programming.

Firstly what is sequence?

Sequence describe a flow or a sequence of operation, example a production operation such as: making cookie, CIP, produce soft drink bottle, pasteurizing.

TO understand more about sequence, I will share about S88, it stands for ANSI/ISA-88, is a standard addressing batch process control. It is a design philosophy for describing equipment, and procedures.

The scope of the ISA/ANSI S88 is to provide guidelines for the design and specifications of batch control systems:

- Firstly, To define terminology specific to batch control systems that will encourage understanding between manufacturers and users.

- Secondly,To define Physical model; a hierarchical physical model of batch system

- Next, To define Procedure; a hierarchical software model of batch system

- Next, To define recipes that link the Procedure to the Physical model

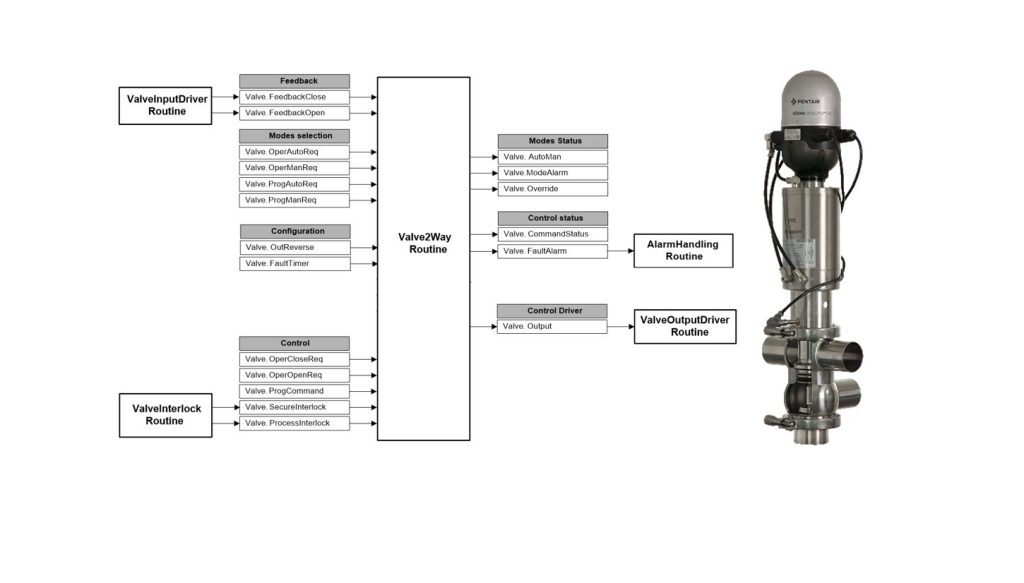

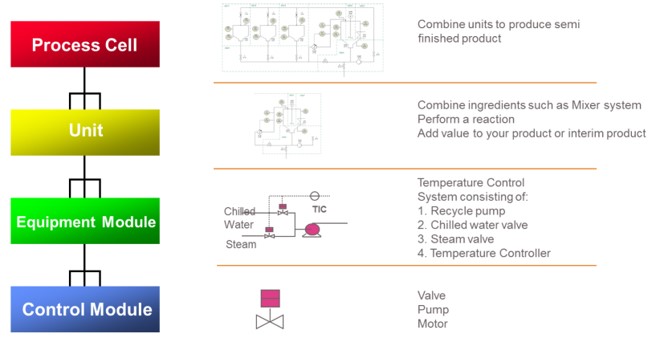

Next, I will share about S88 Physical Model, we have 4 layers:

Process Cell : The entire collection of equipment needed to execute a single recipe from start to finish batch

Unit :

– Usually centered on a major piece of process equipment

– Frequently operates on or contains the complete batch

– May operate on or contain only a portion of the complete batch

– Cannot operate on or contain more than one batch at a time

Equipment module: Group devices for performing one or more specific processing activities

Control module: “connect” software to the process through actuators and sensors with all elements treated as a single entity

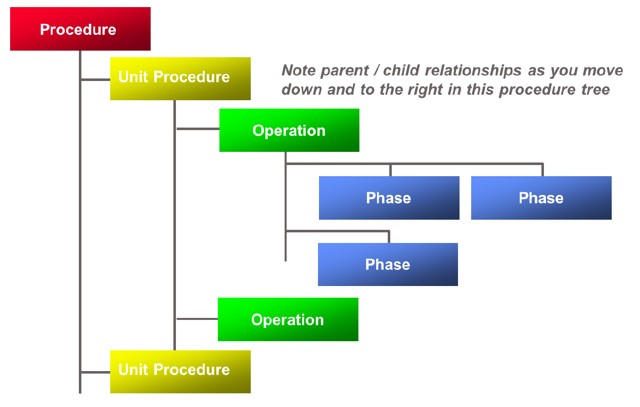

Next is Procedural Model that is forming for our program structure for sequence and phase.

We have 4 levels:

Procedure (recipe level):

– The overall strategy for making a batch

– Consists of an ordered sequence of unit procedures

Unit Procedure:

– The subset of a procedure that occurs within a single unit

– Consists of an ordered sequence of (one or more) operations

Operation:

– A sequence that causes a significant physical or chemical change within the batch

– Consists of an ordered sequence of (one or more) phases

Phase:

– The smallest element of procedural control, capable of causing one or more actions

More detail explanation: https://www.youtube.com/watch?v=8X-ZKS45zZk

Flexbitautomation.com